What types of welding seams are there?

Table of Contents

What is the difference between butt and fillet welds?

The main difference between these two types of weld is the type of joint. With butt welds, both workpieces are arranged in one plane. In fillet welds (e.g. in a T-joint) they are at an angle to each other and form a fillet joint.

What types of joints are there with welded seams?

- Butt joint

- T-joint or double T-joint

- Inclined joint

- Corner joint

- Multiple joint

- Parallel joint

- Lap joint

- Breaded joint

Butt Joint

With butt joints, the workpieces lie in one plane. These can have different shapes at their ends and thus the seam shape determine. More on this in the section:What shapes can weld seams have?

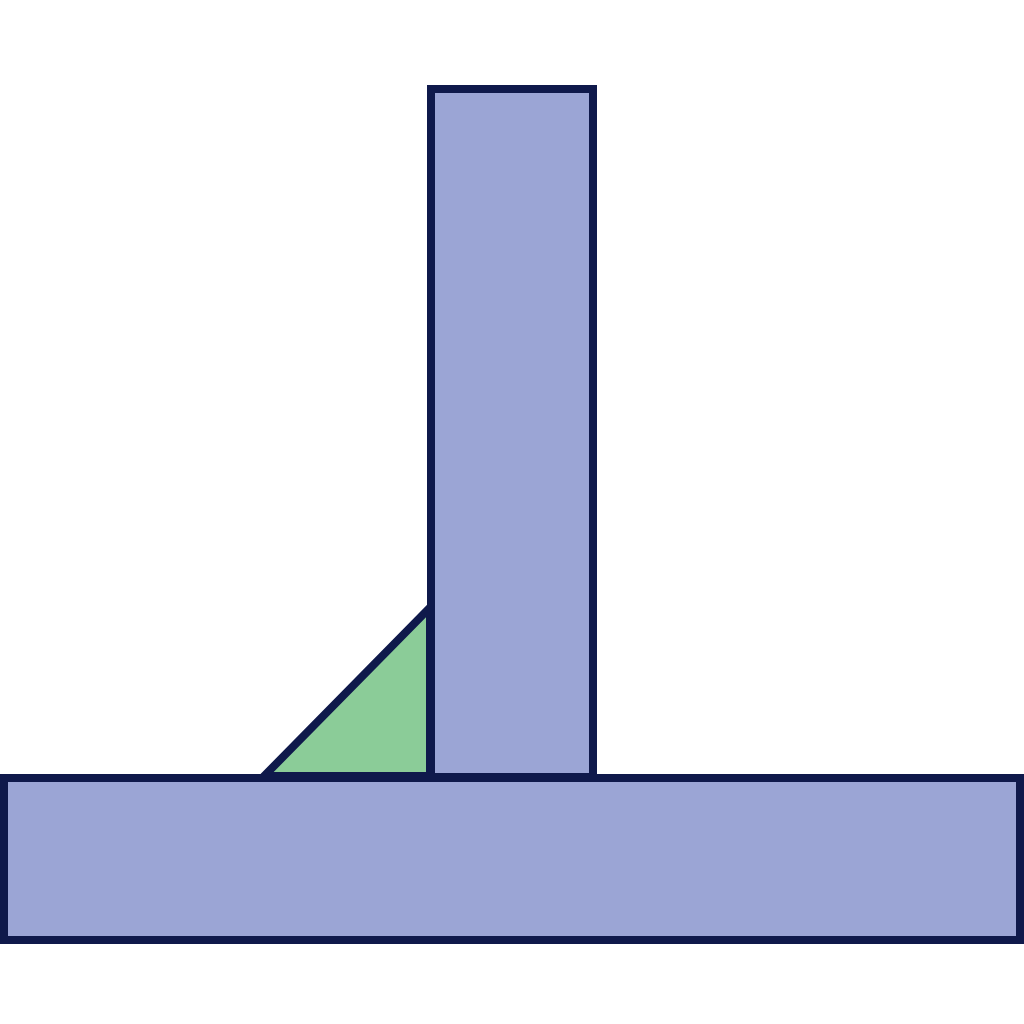

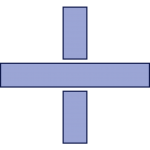

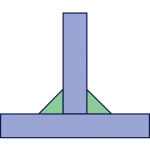

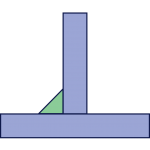

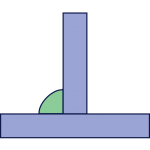

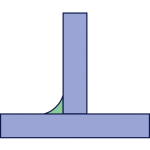

T-Joint & Double T-Joint

The T-joint is a good example of a fillet weld. The Workpieces lie at a right angle to each other, with one protruding over the other. A double T-joint occurs when one piece is attached from both sides at right angles to another to be welded.

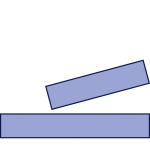

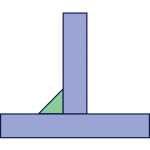

Diagonal Joint

In the case of an oblique joint, a workpiece is welded on at an angle. In contrast to a right angle in the case of a T-joint, this angle is sharper or flatter.

Corner Joint

The ends of both workpieces abut at a corner joint. It does not matter whether they are at a 90 degree angle or any other angle (< 180 degrees) to each other.

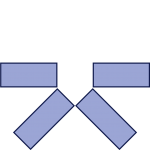

Multiple Joint

If 3 or more pieces lie against each other, this is called a corner kick. These do not have to be symmetrically aligned and can lie at different angles to each other.

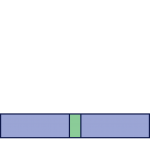

Parallel Joint

If two parts are parallel to each other, they can be welded together with a parallel joint. A spot or hole seam, for example, is suitable for this purpose.

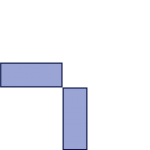

Lap Joint

The overlap joint exists when several parts lie parallel on top of each other and overlap. In this case one workpiece protrudes over another.

Flanged Joint

If two parts are bent and lie with their rebate against each other, they can be welded together there. This type of joint is called crimp joint.

What shapes can weld seams have?

These 11 are the best known.

- Fillet weld

- I-seam

- V-weld

- HV seam

- Y-seam

- HY seam

- U-seam

- Steep-flank seam

- Spot weld

- Punched seam

- Sutured

Other seams are bead and burr seams. However, these are less well known and will not be considered further at this point. Besides the simple variants, there are also double welds (e.g. double fillet weld) and combinations (e.g. V-weld with counter-weld).

Which weld seam symbols are there?

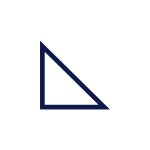

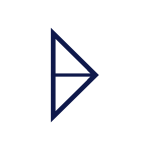

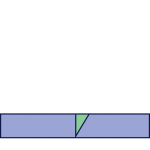

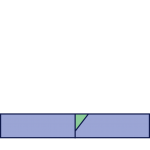

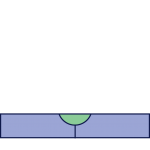

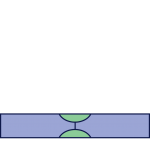

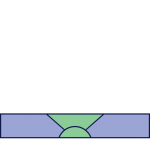

Fillet Weld and Double Fillet Weld

A fillet weld or double fillet weld is represented by one or two right-angled triangles with the hypothenuse facing to the right. In a double fillet weld, a fillet weld is drawn from both sides of a workpiece.

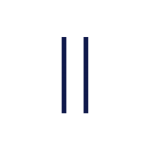

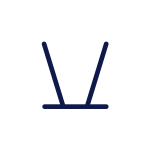

I-Seam

With an I-seam, the weld seam and the ends of the workpieces are straight. It is visualized with two parallel lines of equal length pointing downwards.

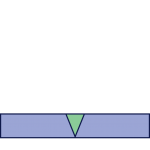

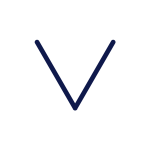

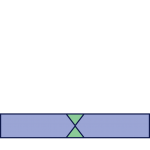

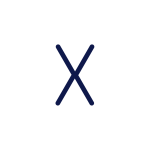

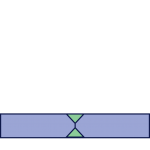

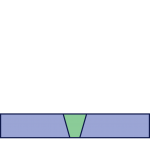

V-seam and DV-seam

The V-seam tapers towards the root and the two workpieces are bevelled. If a V-seam is drawn from both sides and the roots of both seams meet, it is called a DV-seam. These are represented by a V or a cross (cross-section of both V seams).

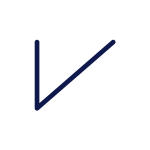

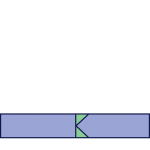

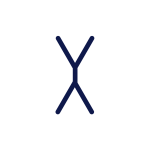

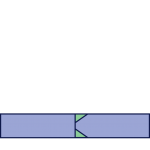

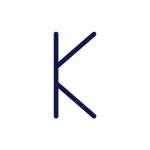

HV-seam and DHV-seam

In a HV seam, only one workpiece is bevelled and the other is straight, so that the root is even more pointed than in a V seam (halved). A DHV seam is welded from both sides and the roots meet. They are symbolized by a vertical and a diagonal line ending at the bottom of each other (HV symbol) and a combination of the HV symbol and its mirrored counterpart, so that the symbol resembles a K (DHV symbol).

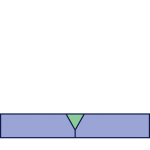

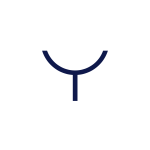

Y-seam and DY-seam

A Y-seam tapers to the root (both parts bevelled with a straight rest) but is not welded through. Similarly, the roots of a DY seam do not meet. These are symbolized by a Y or cross-like symbol where the center represents the non-latching roots.

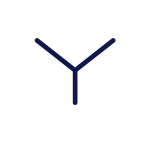

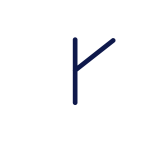

HY-seam and DHY-seam

Analogous to the (D)Y seams, the (D)HY seams represent a halved variant of these. Only one workpiece is bevelled and the other is straight. The symbol for a HY-seam is a vertical line with a “branch” to the right. The K-like symbol of a DHY seam is stretched in the middle (because of the roots not being welded through).

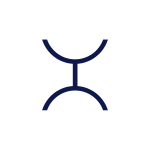

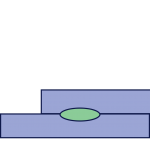

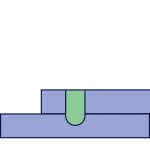

U-seam and DU-seam

In a U-seam, both components have an inward curvature and a part that lies straight against each other. The root is not welded through, which is why the symbol corresponds to a half oval with a vertical line. The DU seam has curves on both sides of the workpieces, but the roots do not meet. The symbol of a DU seam therefore adds another half oval to that of the U seam.

Steep-flank seam

A steep-flank seam is pointed like a V-seam, but is flattened at the root end. The symbol is a truncated V that ends in a horizontal line.

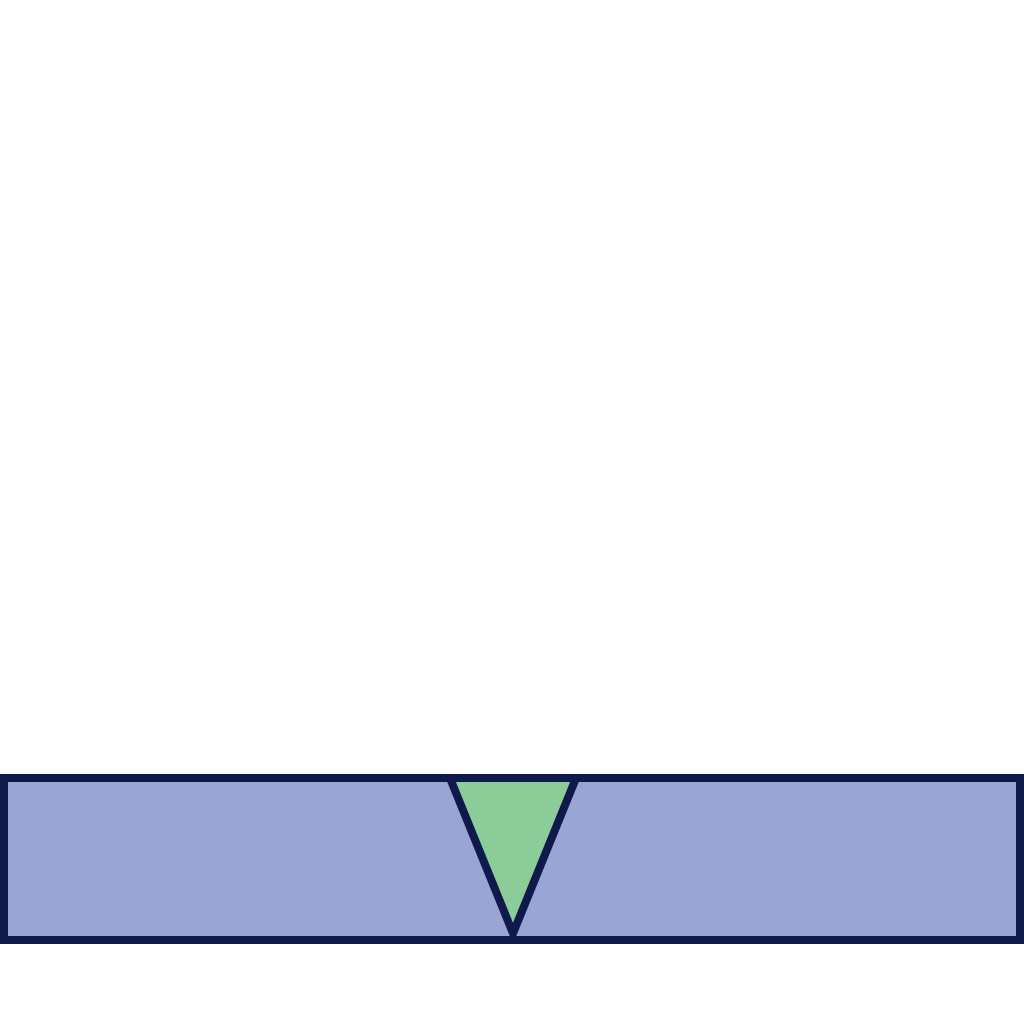

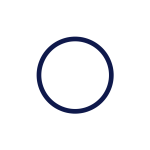

Spot Weld

A spot weld is used for parallel or overlap joints and is located on the outer edge of the workpieces. The symbol of a spot weld is an unfilled circle.

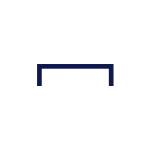

Punched seam

In the case of a hole seam, welding is carried out through a parallel or overlapping workpiece into another. It is represented by a square bracket facing downwards.

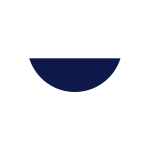

Counter Seam

A counter seam is located on the back of a component and is round. It is represented by a filled half oval (curved downwards). It can be applied in combination with single-sided seams. The symbols of the seams are then combined (e.g. V-seam with counter seam).

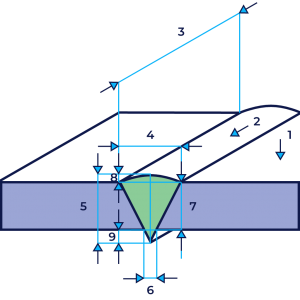

What other dimensions are available for welded seams?

- Base material

- Weld metal

- Seam length

- Seam width

- Total seam thickness

- Root width

- Actual seam thickness

- Weld Overlap

- Root elevation

These can be used to characterize seams in different ways. Depending on conditions and materials, these properties must be correctly selected to ensure the strength and stability of the weld. The following sections deal with these dimensions and shapes.

Which weld seam elevations are there?

The seam elevations shown there or the outer shape of the seam can be divided into three types: Flat seams, arched seams and coved seams.

Flat Weld

If a seam is finished flat (seam camber = 0), it is called a flat seam. The actual seam thickness can be determined quite easily as the height of the triangle, as it is flush.

Camber Weld

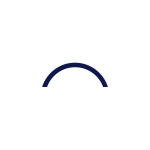

A weld seam that has a convex shape (elevation > 0) is called a cambered seam. The actual weld thickness is determined as the height of the triangle between the root and the two transitions between the weld, the camber and the base material. The corresponding internal flat seam is drawn in and its height is determined.

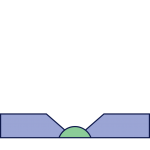

Hollow Weld

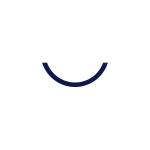

If the elevation of the weld seam is < 0 and is therefore concave, it is called a hollow seam. Here, the actual weld thickness is determined as the height of the triangle from the root to the intersection points of the tangent of the curvature with the transition between the weld and the base material. This is analogous to an internal flat seam that ends at the belly of the curvature.

What does a good weld look like?

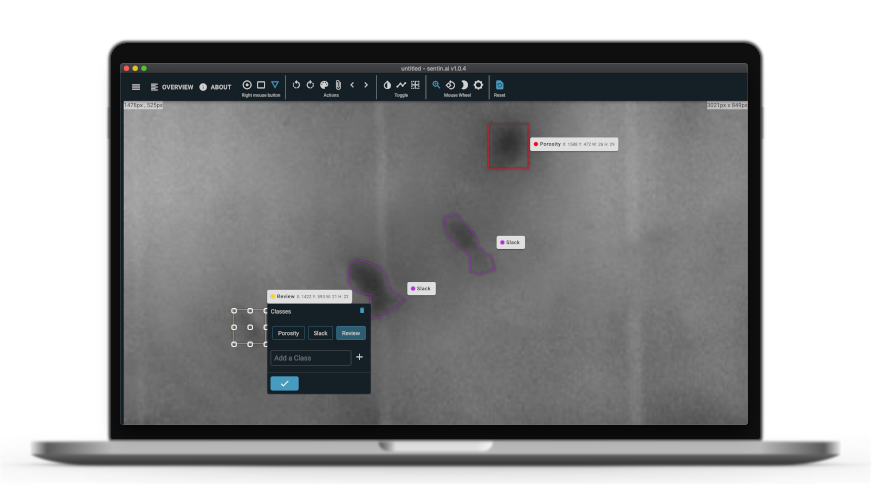

In order to save time and nerves during testing and evaluation, you should use the right tool. The sentin EXPLORER facilitates the evaluation by automatically analyzing and marking of discrepancies.

The 5 Types – What Is Non-Destructive Testing (NDT)?

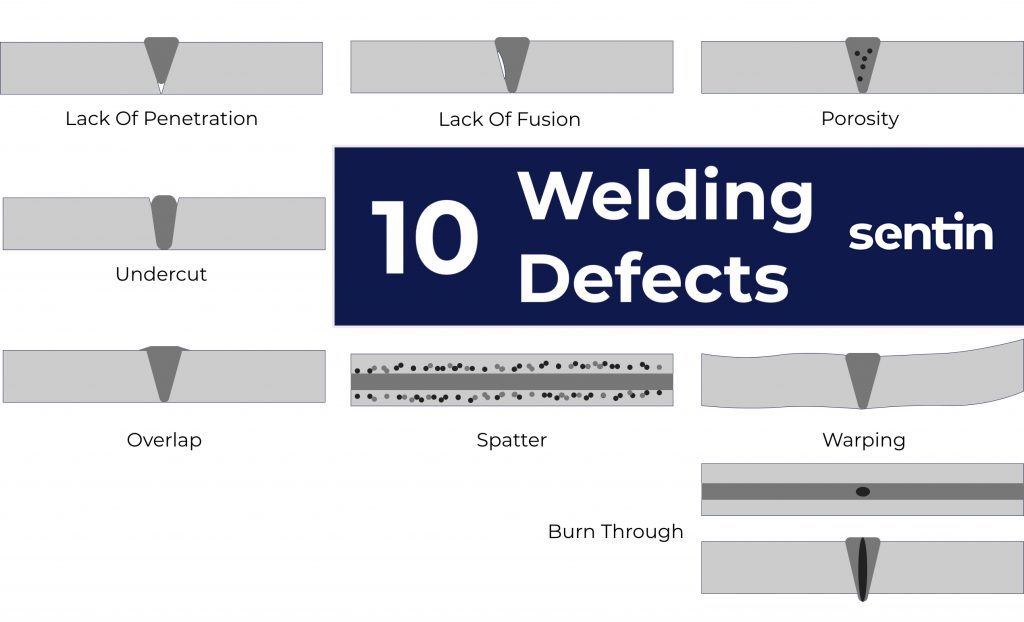

External and internal characteristics play a role in the evaluation of welds. Non-destructive material testing such as visual inspection (visual inspection – VT) or imaging methods (e.g. radiographic testing with X-rays or gamma rays – RT, or ultrasound with phased array – UT) can be used to examine them for cracks or pores, for example. Learn more about these and other defects in the following article.

Sources:

- Drawing representation of welding seams – Prof. Dr.-Ing. L. Müller – university of applied sciences Hamburg

- Weld seams (overview)– Baustatik Wiki – University of Applied Sciences Wismar

- Special seminar: Symbolic representation of welded joints – SLV Fellbach – GSI SLV

Comments:

The illustrations and symbols used here have been created by the company itself and do not correspond exactly to the illustrations in the standard. You are welcome to use them, but you should consult the standard illustrations for your technical drawings.

Furthermore, the information has been carefully compiled from various sources. Nevertheless we refer to our disclaimer at this point.