Industry 4.0 refers to the digitization and networking of industrial production after the three great industrial revolutions. Non-Destructive Testing and Evaluation 4.0 (NDT & NDE) mainly depend on improvements of NDT/E equipment. At this point, there is a special relationship between progress in industry 4.0 and NDT 4.0. One technology which influences both is Artificial Intelligence (AI), which in this application focuses on image processing and evaluation.

Probability of Detection (POD) is a common metric for NDT that helps to establish compliance with standards for inspection quality. This article discusses the contribution of these new technological developments in the NDT process, to improve the Probability of Detection (POD) by making use of the digitalization brought by the industrial revolution.

Keywords: Probability of Detection, Artificial Intelligence, Discontinuity, Defects, True Positive, False Positive, Non-Destructive Testing, Non-Destructive Evaluation, NDT 4.0, NDE 4.0, Industry 4.0, Industrial Revolution, Automatic Defect Recognition, Image Enhancement, Denoising.

It is based on the Paper “How can NDT 4.0 improve the Probability of Detection (POD)?” in The e-Journal of Nondestructive Testing – ISSN 1435-4934

Inhalt

What is Artificial Intelligence (AI)?

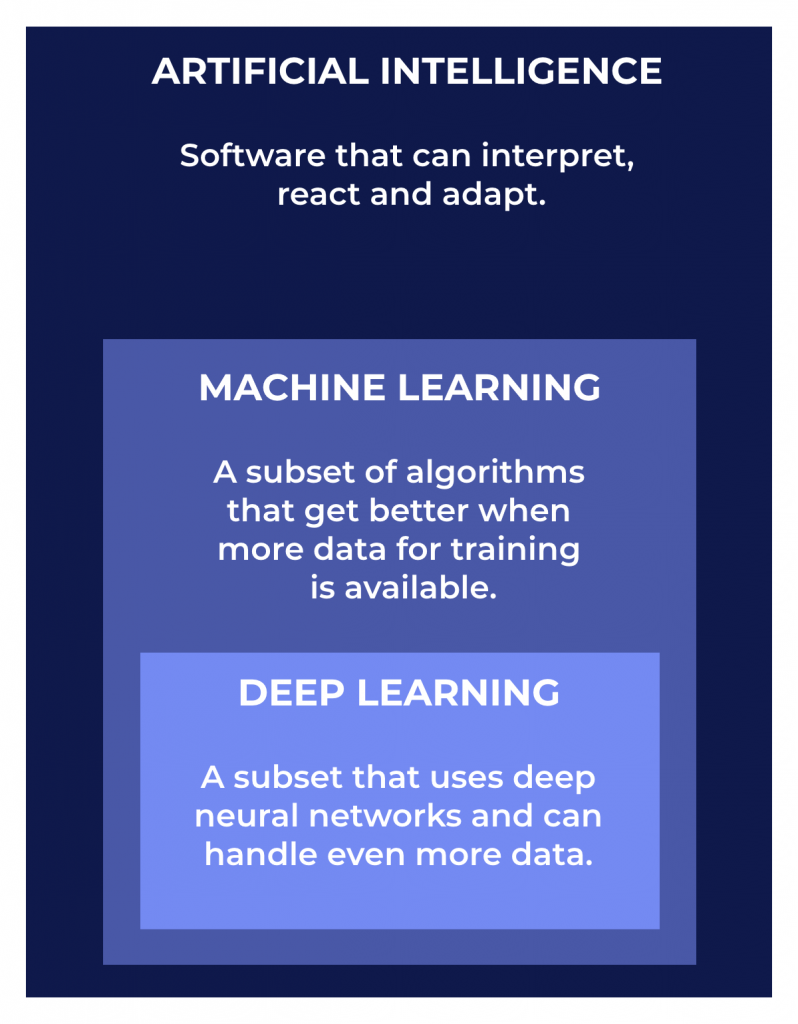

Artificial Intelligence (AI) is the term used to describe programs that can perceive, understand, react and adapt their behavior to the situation. The term is often used as a synonym for Machine or Deep Learning and is seen as a contrast to rule-based programming.

An AI model can be regarded as an evaluation software. In the case of Deep Learning, it is a so-called network of evaluation functions, which can thus learn arbitrarily complex relationships. The parameters of the evaluation functions, the network architecture and the interface for querying evaluations then represent a model that can be used elsewhere, e.g. in another software or plant.

AI is one of the most important technologies in NDT 4.0.

If you want to learn more about AI in general checkout our FAQ.

Where can Artificial Intelligence (AI) be used for NDT 4.0?

In the context of NDT 4.0, many new and old areas of application for AI can be found along the NDT value chain. These include, for example

- Data analytics – insights into order and test data

- Digital twins – modeling and predictions

- Use in the evaluation / inspection process – Improved equipment / inspection methods

- Critical Item / Image Detection (CID)

- Single Item / Image Detail Analysis (SIDA)

- Denoising, Superresolution, Data & Image Enhancement

- Automatic Defect Recognition (ADR)

Use case 1: Data Analytics

Artificial intelligence can be used in the area of order and inspection data to gain new insights and generally create transparency. Data analytics in NDT can be used to analyze test sequences and processes more precisely. However, this requires sufficient digital data.

Sales increase & cost savings:

One area of application is the analysis of customer, order and supplier data. Here, sales increases and cost savings can be realized by using AI to uncover patterns that arise in orders, for example. It is conceivable, for example, that many individual orders for testing equipment or consumables (such as films or chemicals) from different company divisions could benefit from discounts and economies of scale in bulk orders.

Time eaters in the inspection process

Another application example is the detection of bottlenecks in the inspection process. These can be varied and are very individual for each company. One case that occurs frequently, however, concerns constant media breaks in the workflow. These result, for example, in things being printed out several times and then digitized. Ideally, the inspection should run as digitally as possible via a networked infrastructure.

Critical measuring points / infrastructure / equipment

In addition to the procedures in the testing process, AI and data analytics can also be applied to test objects and other items. For example, pattern recognition can reveal that a certain piece of test equipment lasts twice as long on average as another. Or that a certain measurement configuration in the system constantly needs to be repaired. Or that a certain system, although it is much smaller than others, still takes much longer to test.

Use Case 2: Digital Twin

The use of digital twins is a core technology of NDT 4.0. On the basis of collected data, simulations or models can be used, for example, to make recommendations for action and predict decisions or events. The digital twin is then a digital entity that has exactly the same properties as the mapped element. As a result, the behavior and condition of the real object can be precisely viewed and predicted.

Artificial intelligence can be used as the basis for such models. Examples can be

- Simulation of infrastructure, e.g. corrosion over time

- Digital prototypes and testing in production, e.g. cast parts

- Project planning, e.g. of pipelines

- Prediction of maintenance (predictive maintenance)

Use case 3: In the evaluation / inspection process

The direct use of artificial intelligence in the evaluation and testing process offers some potential for improving NDT equipment and methods. Some examples of image-based testing (e.g. radiographic testing) are presented below, as these are easy to understand. However, there are also applications for other inspection methods such as ultrasonic testing. Many aspects of the approaches presented are transferable to other methods.

Critical Item / Image Detection (CID)

In NDT, there is often not just one test object that needs to be examined. Evaluators are often involved with a large number of images, e.g. in radiographic testing of weld seams or corrosion testing. Many of the images are without complaints or indications and only a fraction is particularly critical.

With the help of artificial intelligence and the parallel processing of several recordings (so-called “batch processing“), recordings can be pre-sorted for evaluation.

Critical item detection can be used for non-image-based inspections, e.g. for classic ultrasound or other sensor data, in order to process these in parallel.

Critical image Detection, on the other hand, offers the option of processing image-based inspection such as radiographic testing or image recordings from visual or (dye) penetrant testing as a batch.

The aim is to determine whether a recording is critical or not.

This involves finding recordings that, for example

- Have poor quality

- contain film errors or blemishes

- Duplicates or manipulated recordings

- Missing IQIs or identifications

- Show indications of possible defects

Single Item / Image Defect Analysis (SIDA)

In addition to Critical Item Detection or Critical Image Detection (CID – batch processing), individual images can also be processed in detail with AI. The aim here is not only to determine whether an image is critical, but also why and where.

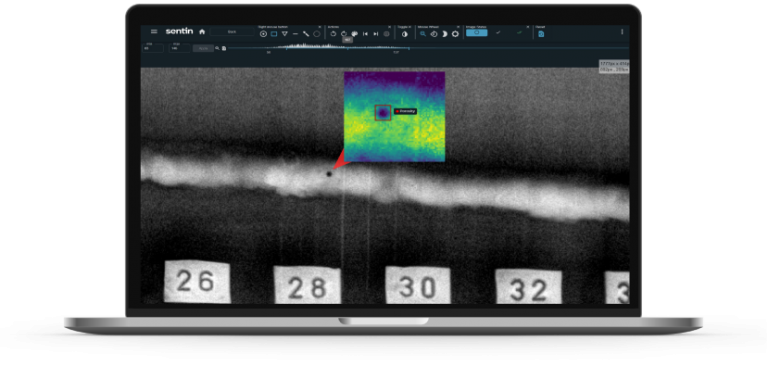

In single item detail analysis or single image detail analysis (SIDA), the image is shown to one or more AI models and the results are processed visually, e.g. in the image, and stored in the data container, e.g. DICONDE.

Single item detail analysis can be used for non-image-based inspections, e.g. for classic ultrasound or other sensor data, to evaluate a measuring point in detail.

Single Image Detail Analysis, on the other hand, offers the possibility of checking image-based inspections such as radiographic testing or image recordings of visual or dye penetrant inspections in detail in a similar way to a human being.

Entire test sequences and work steps can be taken into account. The combination of different AI models and algorithms helps to make evaluation easier for the evaluator.

Images are examined for the following parameters, for example:

- Film defects or blemishes in the area to be evaluated

- Text recognition for identification

- IQI evaluation

- Comparison with test parameters

- Wall thickness measurements and wall profiles

- Defect detection of e.g. weld seams (ADR)

- Standard validation, e.g. for defect sizes

- Recognition of test configurations

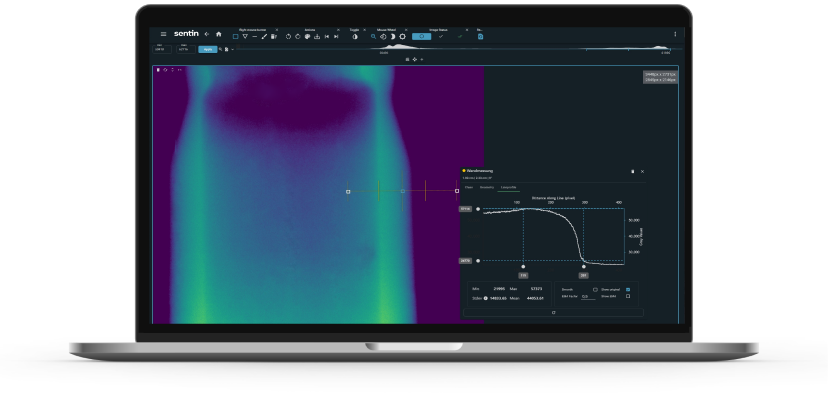

- Application of further algorithms, e.g. denoising, superresolution, data & image enhancement

Denoising, Superresolution, Data & Image Enhancement

Until an image is displayed on a monitor or a film, several environmental factors can lead to a distortion of certain parts or a general noise overlaying the whole image. There are many causes for noise, which does not allow for rule-based enhancement. One example of noise is salt and pepper noise, where singular pixels are either fully black or white. Another example is gaussian noise, which is distributed uniformly over the picture. The standard method for estimating noise is the signal-to-noise ratio (SNR), which is also mentioned in several standards for weld image inspection.

The conventional approach for denoising is to use static filters (like low/high pass), which are applied to the image as a convolution. The main disadvantage of these filters is the missing spatial resolution since they treat all parts of the image in the same way. In this regard, modern AI algorithms can interpret information locally and create and combine several hundreds to thousands of filters, where each filter can concentrate on a different feature in an image. Doing this manually would mean necessitate dividing the image into multiple patches (e.g., 16×16 pixels), and optimizing each view based on your knowledge and the position of the patch in the image and putting everything back together.

These types of AI models are used heavily in photography to enhance low resolution images, correct lightning or when applying filters. A topic we focus on it the development of these AI algorithms for application in digital radiography/radioscopy.

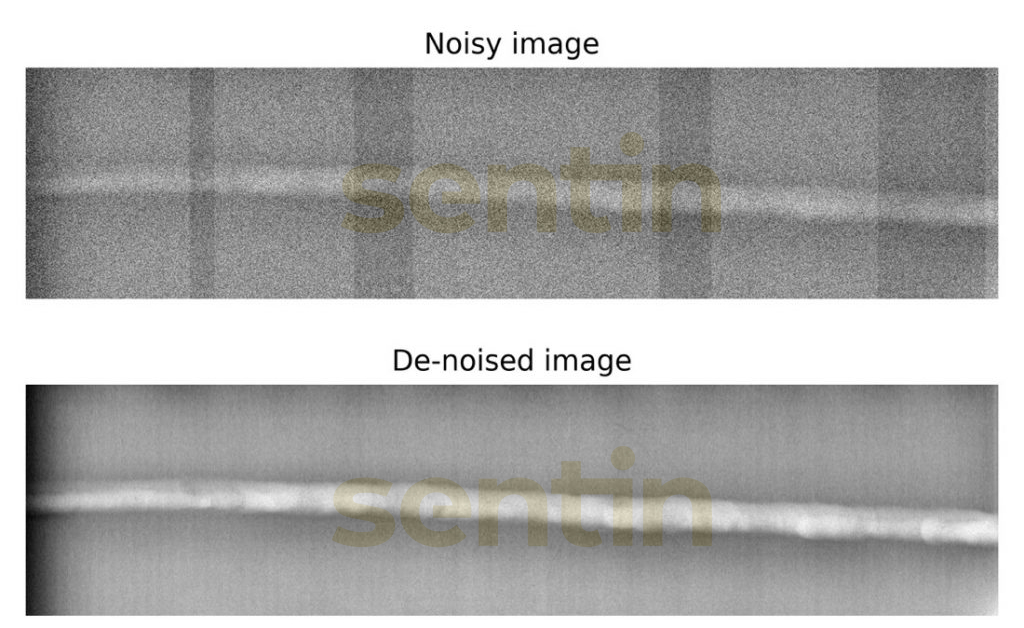

For example, noise in weld images is a major factor when using national standards. Therefore, a denoising is useful to provide a clear representation of the defects. This improves the detection rate of a human observers, as well as time spent on one image. An example can be seen in Figure 2, where a noisy weld image (top) with several artifacts and different noise granularity is shown. If an AI could reconstruct the image and react on different noise types automatically it could transform it to a less noisy image (bottom) and keep major image details. The advantage of such an AI algorithm is that local features (e.g., defects, weld edges, background, etc.) can be treated differently based on their spatial occurrence.

For training such an AI you would need to have data with little noise, showing the algorithm examples of good images – e.g. by performing some shots with long exposure time. Afterwards you can put noisy images into the model and it will output the denoised images. (Disclaimer: Figure 2 is an exaggerated example, because latest results must not be shown publicly due to non-disclosure agreements. It does not represent the current state of the technology. Nevertheless, it shall visualize the potential of an AI algorithm.)

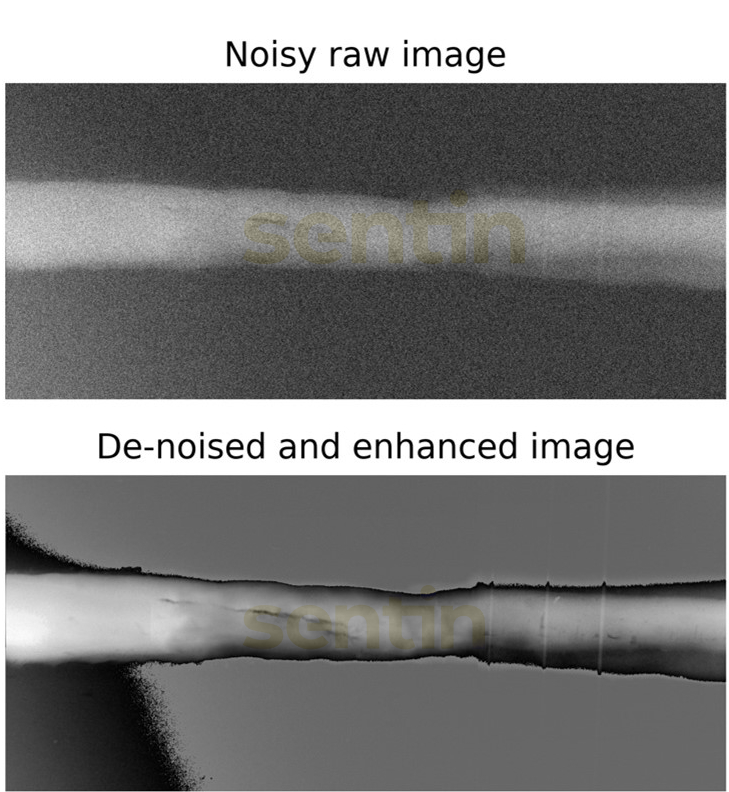

Other than denoising, Figure 3 shows an example of image enhancement, where a crack in a weld can be observed. Depending on the value range that is presented to the human observer, different depths can be seen. Thus, an observer often needs to take two or three views to fully see all defects in all depths. An AI algorithm can help to enhance every single defect in a way that a human observer can see all defects in one image. This saves time and improves the detection rate or POD of a human observer. For practical usage this also means that you can use images that are taken with imperfect conditions such as low exposure time, while maintaining valid image quality with post processing. (Disclaimer: Figure 3 is an exaggerated example, because latest results must not be shown publicly due to non-disclosure agreements. It does not represent the current state of the technology. Nevertheless, it shall visualize the potential of an AI algorithm.)

(Automatic) Defect Recognition - ADR

In addition to the areas of application presented above, AI is also capable of accurately detecting errors or defects in an image. Although this detection is not yet the standard in NDT, it is another tool that helps human evaluators to recognize faster and more precisely. In addition, the AI is stable and is not affected by factors such as fatigue.

For defect recognition, a supervised AI is used. This AI is trained based on given examples of images with its correct labels. In supervised vision, three major types of AI exist. They are image classification, object detection and instance segmentation. The first one returns one label per image (defect or no defect). This type of AI is only suitable for use cases where only one object is present per image and if the occurrence of this defect implies a rejection of the entire sample (cracks in most standards).

Object detection draws a bounding box around a defect. This is useful, when several different defects can occur, but a human observer needs to decide whether the part is scrap or not. The last one, instance segmentation, is a prediction of the exact polygon of a defect. Although this algorithm needs the most data, it is the perfect for quantifying defect. E.g. a lot of standards for weld images need you to measure defects and ensure that these are below a given threshold in size. Those geometric coherences can be calculated for detected defects and autonomously reject samples.

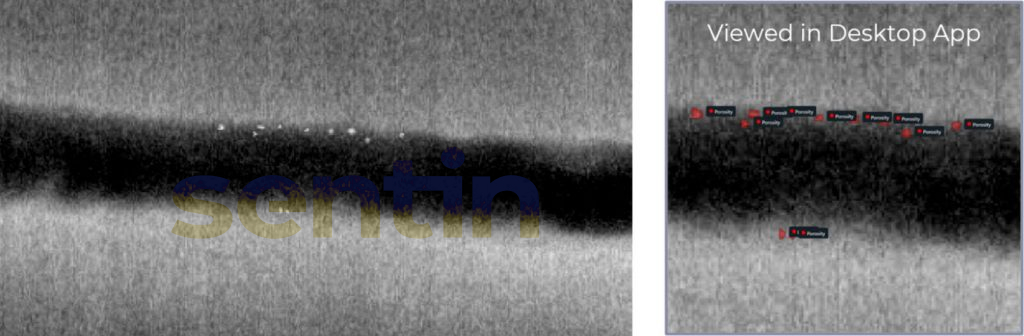

Figure 4 shows an example of a weld image with porosity. Using a different AI algorithm, that can detect defects or discontinuities, it can be displayed and highlighted like the right part of the image. Although defect recognition detects defects directly, image denoising and image enhancement are often useful as a pre-processing step to make an algorithm more robust and reduce the number of images needed for AI Model training. Thus, both approaches for AI work well together to help the evaluator do their best work.

Even though training of those algorithms is time consuming, the execution of a trained algorithm is extremely fast. For images with a normal size (e.g., 1,200 x 1,800 pixels), the evaluation times of under 50 milliseconds are to be expected – depending on the hardware used.

What is the current performance of NDT (without AI)?

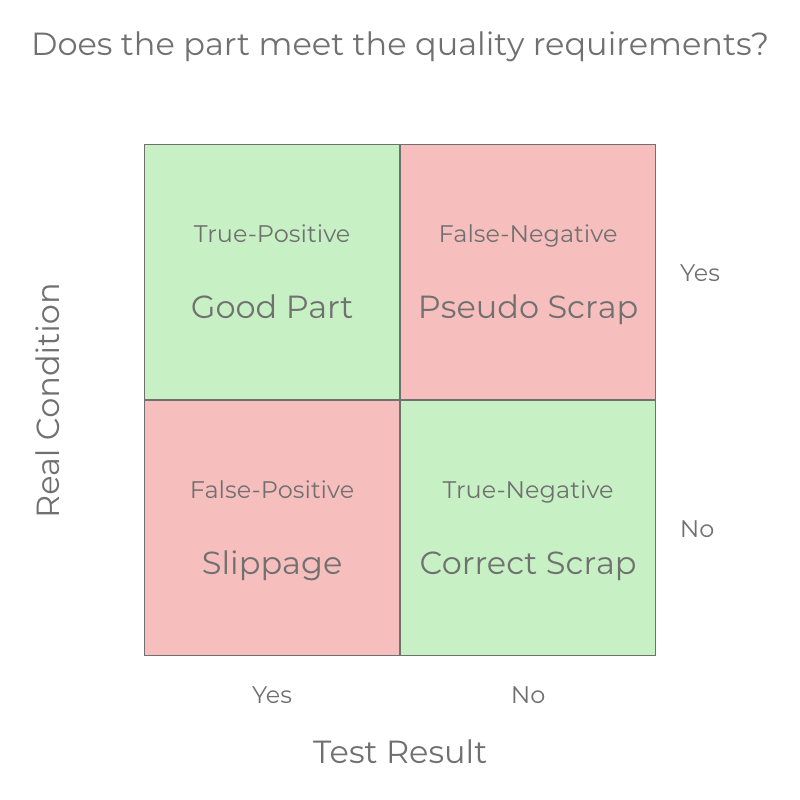

In Data Science and Artificial Intelligence, metrics are important when evaluating the result of a given method. For a binary decision problem, the most prominent metric is the receiver-operator characteristic. It describes four possible states of a prediction. For example, an algorithm or procedure should detect whether a component has defects or not.

This is a binary decision because it either rejects a sample or not. If the algorithm correctly rejects a sample, it is called true positive and if it is does not reject the sample and the sample has no defects it is called true negative. However, if the algorithm rejects the sample although the component has no defects, it is called false positive. The opposite (component has flaws, but the algorithm does not reject the sample) is called false negative.

In NDT the performance/accuracy for (true-positives and true-negatives) of the the best NDT evaluators is estimated to reach max. 85,2 % POD with 2,1 % PFA, “[…] but the overall results are worse with high false alarm rate.” [3]

What is the Probability of Detection (POD)?

Based on the above classifications we can carry out a test where we give the algorithm, examiner or procedure several samples (e.g. 1000) that are known to have defects or are defect free. The samples are then evaluated and it is decided if they have defects or not. Since we know how the examiner or procedure should perform with this sample set, we can determine how they performed according to the four performance classifications above.

With this method we can analyze data in many ways. A common metric for NDT is the Probability of Detection (POD), which is simply defined by:

POD = True Positive / (True Positive + False Positive)

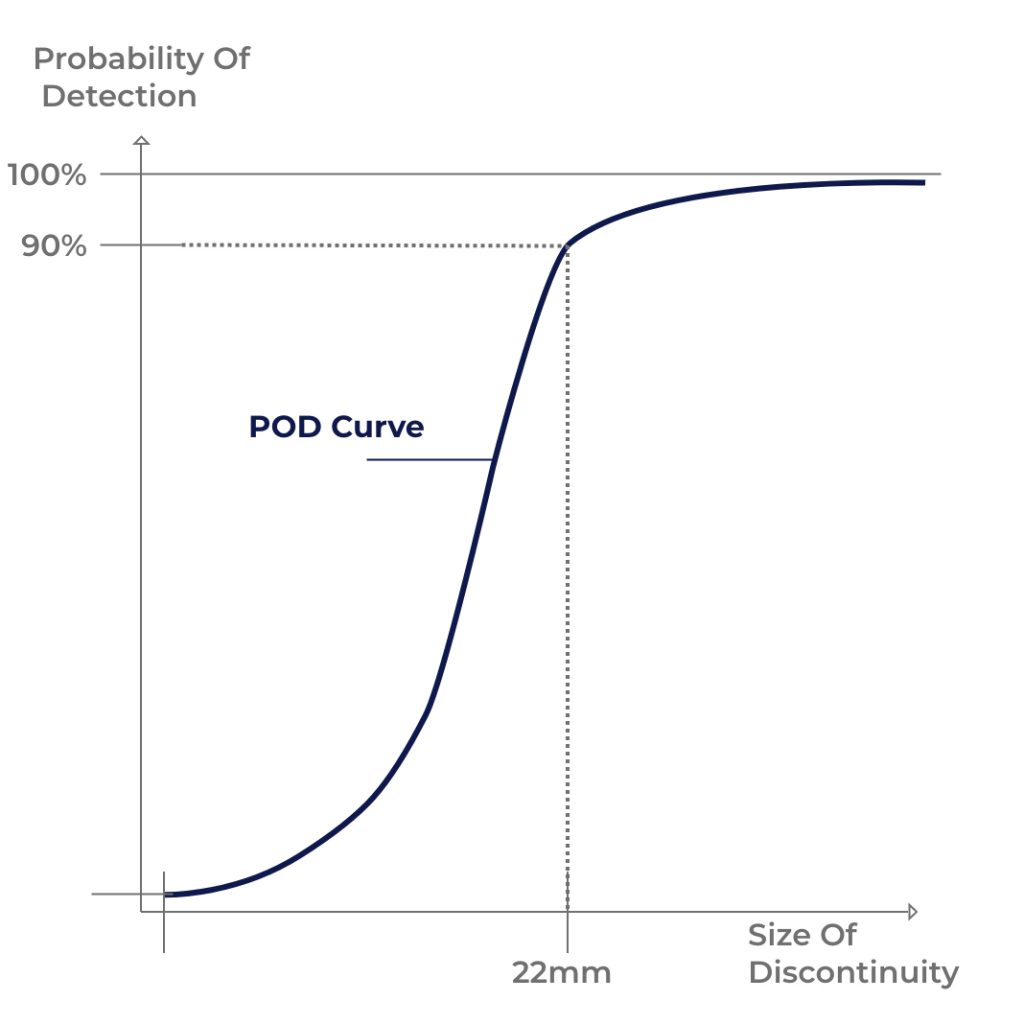

Based on POD, an algorithm can be evaluated based on a different factor. For example, the figure below shows POD values in context of the flaw size for a given component. The probability runs asymptotically against 100%. At the marked point the POD is 90% for a flaw size of 22mm. In the NDT field POD is often interpreted as POD in dependence of flaw size.

If you want to learn more about this check out our article:

How can Artificial Intelligence reduce human factors in NDT?

Industry 4.0 is adopting a wide array of emerging technologies that enhance current NDT methods, resulting in NDT 4.0. Cloud Computing and Storage, Artificial Intelligence, Robotics, Big Data, Blockchain as well as Augmented Reality are among the emerging technologies of the fourth industrial revolution.

Defects are bound to happen in any manufacturing process. Manual part inspection and complex statistical methods (six-sigma) are currently required to have a sufficiently high probability of detection (POD) of known defects. This is especially time intensive, when testing welds e.g. in chemical plants, where weld seams are manually inspected using X-Rays. AI can be used to minimize human errors and helps inspectors find defects.

People looking at the same information may form different opinions. Even the opinions that one person forms may be different based on human factors such as fatigue. NDT is a task that requires a high level of attention. The inspector’s attention and the performance of the inspection system are factors that should be considered when determining the POD. Personality, past work experience, training and fatigue of the evaluator performing this task are among the most important human factors affecting the examination process. The inspector’s evaluation also depends on their perception and their ability to process and remember information. Additional problems are caused by the insufficient quality of the signals or images used. An incorrect classification may result in rejection of a part in without defects (false negative) or acceptance of a defective part that exceeds the limit defined by the relevant standards (false positive).

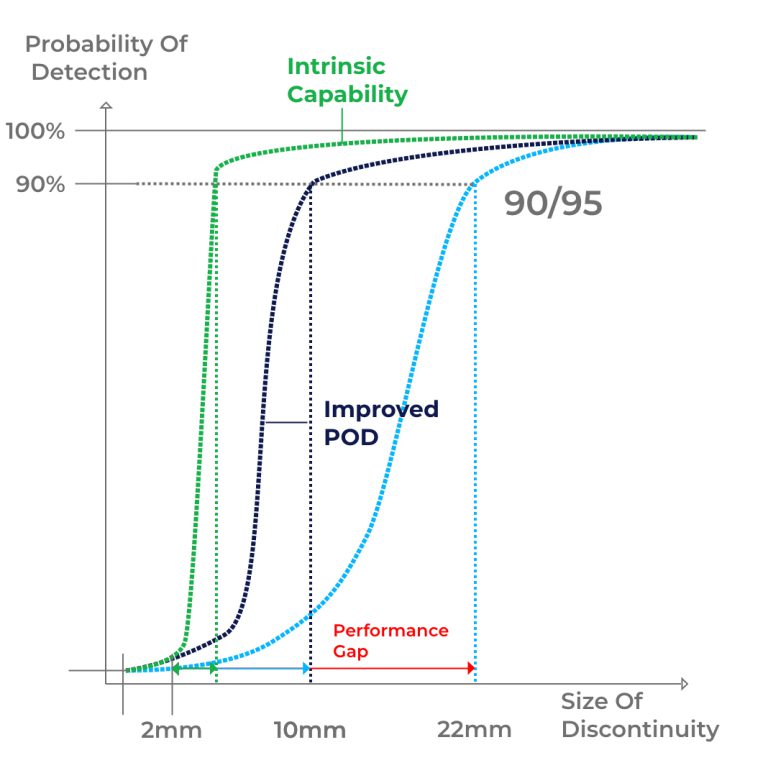

Figure 5 is showing an example of improved PODs. The intrinsic capability is the “best” performance a system can achieve with a small defect size that can be detected with a high probability (90%). The performance gap is the difference between what your system could possibly detect and what it really detects. If an AI can help to detect things earlier/better (smaller defects) the curve will move from the right closer to the best performance reducing the performance gap. [2]

When we are talking about improving the POD we want to detect smaller defects with a higher probability. We can achieve this by reducing disturbing factors. The next lines focus on factors that can be reduced after image acquisition so that companies can use existing equipment/systems just upgrading the image processing with a software.

Example 1: Improving Reliability & Perception with ADR

For a NDT process to be reliable, the entire system of equipment, procedures, and inspectors must be reliable. A technology that can boost perception and reduce the human factors affecting POD improves reliability. That is where Artificial Intelligence can help. AI improves the perception of the inspector by automatically labeling possible defects using Automatic Defect Recognition (ADR). This decreases the human factors affecting the POD like fatigue, motivation or attentiveness. AI also provides an objective second opinion, which may help less experienced inspectors and helps to ensure that inspectors are classifying flaws consistently.

Example 2: Improving Perception & Attentiveness with Image Enhancement.

Another problem affecting the perception and motivation of inspectors and therefore the POD is the image quality. If you can optimize the contrasts and reduce the noise in images in a sophisticated way, then the inspector does not have to choose filters manually and locally, they can focus on the actual interpretation process. If the whole image displays all information in an optimized way, choosing the right enhancement for the right spot, the inspector does not have to choose the right filters manually. This can increase the attentiveness and may help less experienced inspectors observe every detail of the image – finding smaller defects. For the actual image acquisition, AI may also help. Images can be taken faster or with less voltage because the image quality can be increased in detail afterwards overcoming capabilities of classical high-pass filters.

Free checklist

with 24 questions.

Is your company ready for AI & Machine Vision projects?

What sentin does with AI in NDT?

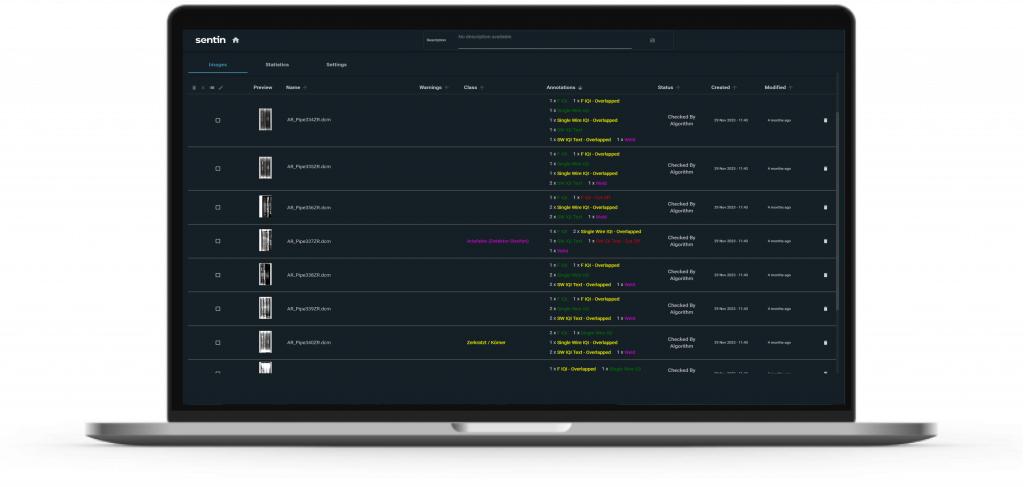

The different AI use cases like data analysis and digital twin, as well as CID, SIDA and ADR and Image Enhancement therefore help to evaluate images & discontinuities as quickly and accurately as possible in a cost-effective way. It improves the detection and classification process of defects, ensuring a high POD, good product quality and application reliability. At the moment the ADR technology is mostly used as an assistance system including a user interface – to meet the standards for human interpretation.

In order to save time and nerves during examination and evaluation, having the right tool for the job is important. We are always working on the integration of the technologies mentioned above into our software, the sentin EXPLORER. Using existing data and tools, you could get a customized software for your evaluation processes without having to be an expert in AI.

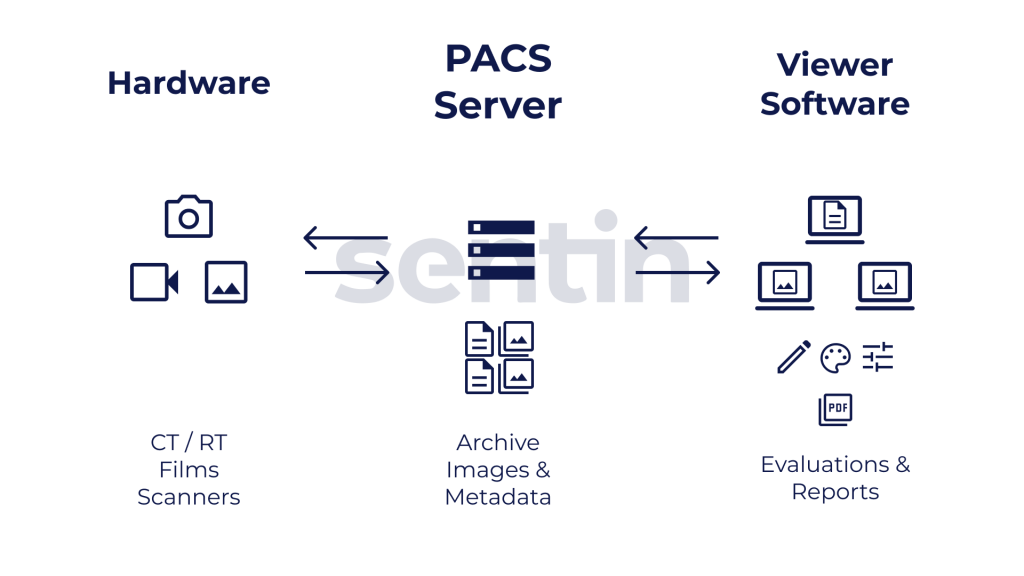

In our case the software is based on modern operating concepts from the field of web technologies. An important advantage here is flexible integration into all operating systems. This technology can be integrated via software as a service either as a standalone product for evaluating image files or in digital NDT image management software.

The software-based evaluation of the images decouples the process of recording and evaluation. Using ADR and Image Enhancement/Denoising it supports the examiner in localizing and classifying errors. In time critical applications, presorting can also be carried out so that images

with the most defects can be analyzed first, so that repair work can be initiated with sufficient lead time.

We want to give you the opportunity to adjust your recognition or image enhancement models as precisely as you want, to get the best results from evaluations and boost your POD. We want your testing to be fast, objective and precise.

References

[1] Vrana, J., Singh, R. (2020). – The NDE 4.0: Key Challenges, Use Cases, and Adaption. DOI: 10.1007/s10921-020-00735-9

[2] Vrana, J., Singh, R. (2020). – The WHY of NDE 4.0 @ Ripi Singh

[3] Fücsöck, F., Müller, C., Scharmach, M. (2005). Measuring of Reliability of NDE

[4] Bertovic, M. (2015) Human Factors in Non-Destructive Testing (NDT): Risks and Challenges of Mechanised NDT DOI: 10.14279/depositonce-4685