The imaging software

with Artificial Intelligence.

Why you should choose it.

Features:

For Inspection & NDT:

Supports 16- and 12-bit images e.g. TIFF, DICOM / DICONDE

PACS interface, Presentation State (PR) handling and import function (DICONDEnize, Upload, Modality)

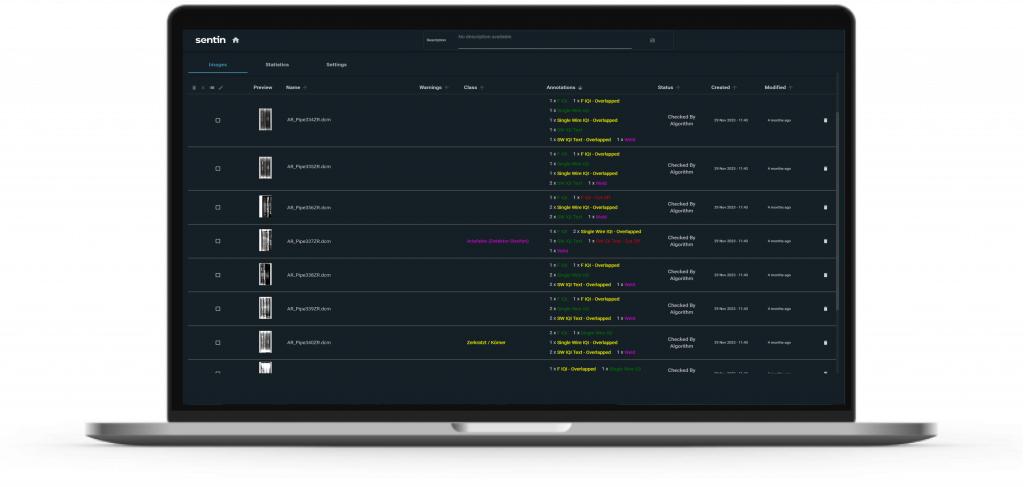

DICONDE study manager (search, filter, sort) and meta data display

Various Statistic Tools: SNR(N), CNR etc.

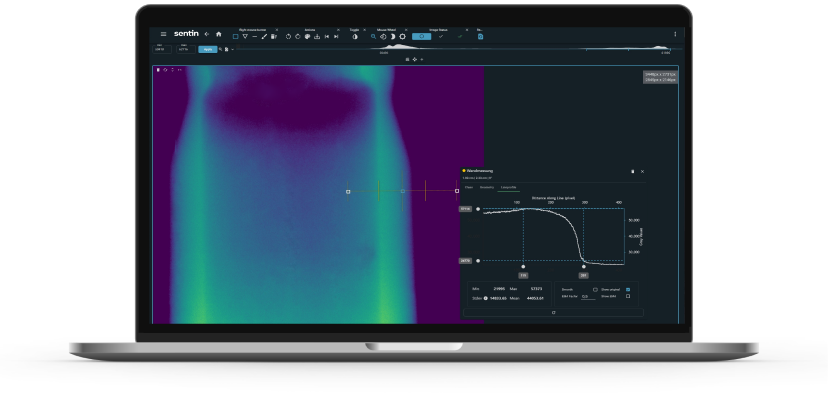

Greyvalue tools for ROI / lineprofiles

Size / Length Reference Calibration tools

Auto. IQI – Double Wire Evaluation

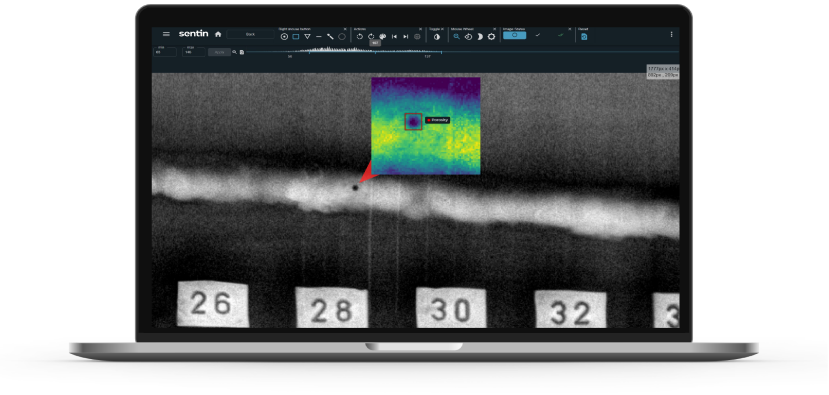

Auto. Pipe Wall Thickness Measurement

Auto. Pipe Diameter Calibration

Norm Validation support e.g. ISO 10675

Various export functions (e.g. .dcm / tiff / png / jpeg)

Advanced sentin NOVA filter for contrast and edge improvement

DICONDE compliant

Supports various standards & codes

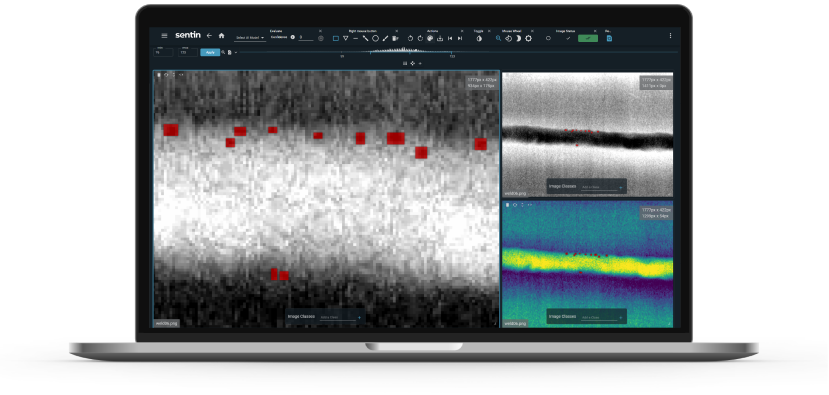

For Displaying Images:

Stepless zoom, shift, rotate and flip

Various display options for brightness, contrast, invert, colormaps etc.

Various image filters (High- / Lowpass etc.)

Displaying several recordings in one display window (matrix view)

1:1 , 1:2, 2:1 Zoom Display

Data Sources:

DICONDE / PACS interfaces

Local File System

sentin Cloud- / Server

3rd Party remote data sources

General:

RGB & Grayvalue images in formats like tiff, dcm, png, jpeg, jpg, bmp etc.

On-Demand and persistent projects to store evaluations in an AI ready data format including auto-save

Interface to AI Models & Workflows

Retrainable AI-Models and Deployment Tools

Dataset statistics and insights

Configurable Evaluation & Settings templates for seamless integration e.g. for ISO 5817

Configurable Toolbar

Configurable Display options (language, font size etc.)

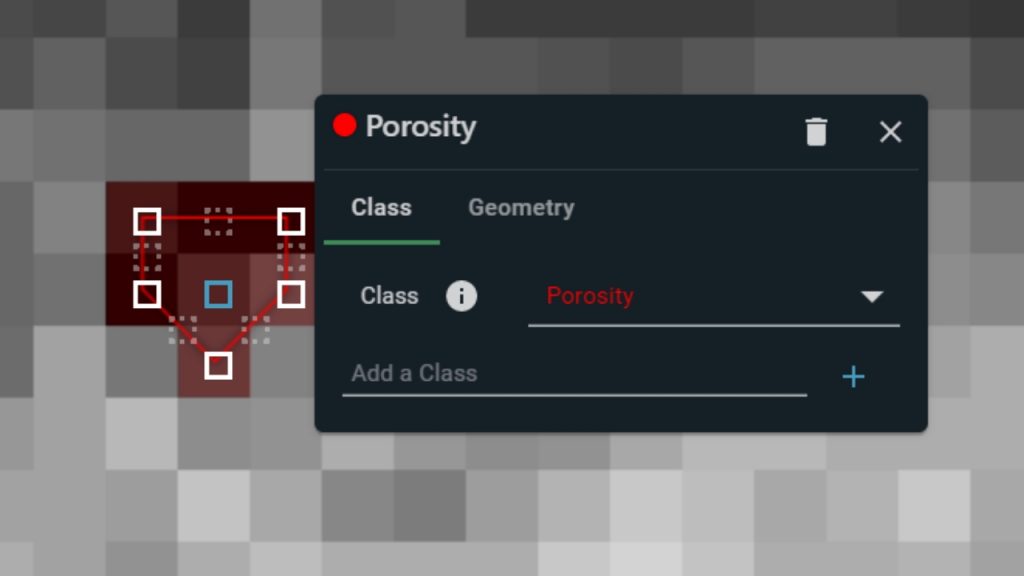

Various annotation types Box, Polygon, Arrow, Line, Angle, Mask, image classes

Freely movable annotations to avoid overlays

Display options for annotations (e.g. transparency, fill, lines, colors)

User notes and comments

Let the AI check all images in the background.

Optional AI Tools:*

Wall Thickness Measurement / Corrosion Detector [X-Ray]

Weld Defect Detector (in-field, manual welds) & Standard Validation [X-Ray]

Weld Defect Detector & Validator (inline, manufacturing) [X-Ray]

CT & X-Ray Image Quality Enhancement / Irradition time reduction

OCR / Text Recognition [X-Ray & RGB]

Inline Surface Inspection [X-Ray, RGB]

Aerial Drone Inspection [RGB]

Inspection Data Anonymization e.g. personal data [RGB]

and others

*Please note that AI Tools may require a setup for your usecase or data type

What experts say:

Dr. Uwe Ewert

Expert for (Digital) Radiography

- Professor and Director off duty

- Chairman of the Technical Committee “Radiology” at the DGZfP for many years

- as well as former head of division at BAM and active at DGZfP

- Member of various standardisation committees of ISO, CEN and ASTM

- received the Berthold Award of the DGZfP (2005), the Röntgen Medal of the city of Remscheid (2009) and the Briggs Award of ASTM-International (2010).

What about hardware and PACS?

sentin EXPLORER already offers many different tools and interfaces to boost your inspections and non-destructive testing (NDT), but to enable you to optimize your processes in a customized manner, we offer various individual services. Whether you are just starting your digital processes or you already have partial solutions, we will pick you up where you are so that you can do your inspections more efficiently and future-proof.

Get in touch.

We are happy to help you.

Dominik Nestler

Business Development

- +49 234 54506170

- contact@sentin.ai