A reliable control of materials is important for the quality and safety of the goods and materials produced. Even today, human visual inspection processes are still strongly employed. But this process does not always lead to the expected success.

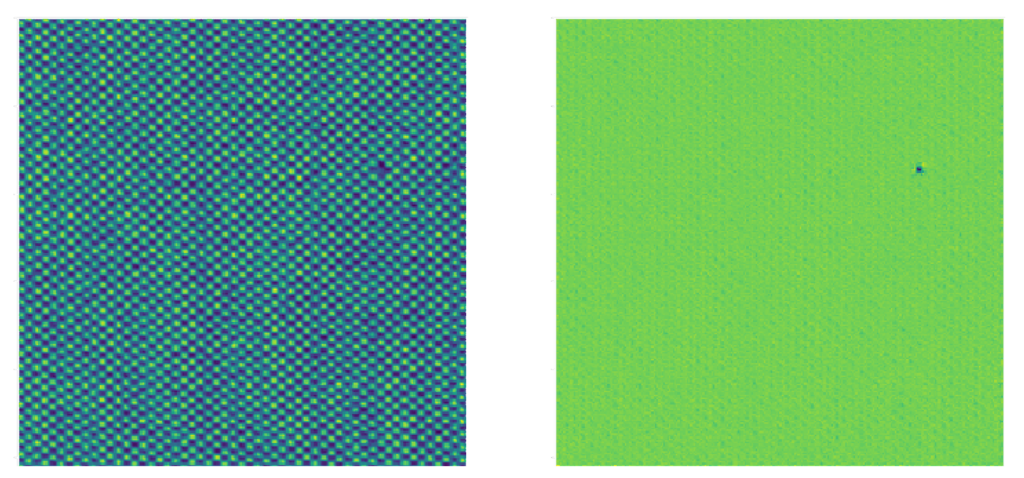

In the example presented, fabric panels are inspected for production faults such as anomalies in the weaving pattern, stains or similar anomalies. The challenge: Due to the fine material, the defects can be very small and therefore difficult to detect. Especially during visual inspection, it therefore quickly becomes difficult to detect all of those anomalies.

Currently, there are four ways to visually inspect fabric panels in a production environment.

1. Visual human examination with the naked eye:

A human inspector inspects the fabrics visually and with the naked eye for defects. This procedure is used regularly, but is highly inaccurate, prone to errors and above all very expensive: on the one hand, the employee’s salary has to be paid, and on the other hand, the company gets charged for complaints and returns due to defects, that were not found. In short: the human being is simply not made for this cumbersome inspection task.

2. Inspection by elaborately calibrated machine:

If a machine instead of a human being looks at the fabric panels, it is usually calibrated at great expense in order to detect any possible anomaly. This method, also known as rule-based machine vision, can work more precisely than the human counterpart, but it still requires permanent and very extensive recalibration if something changes in the material, the product or the environmental circumstances like the lighting conditions.

3. AI method using previously collected images:

Thirdly, there is the possibility of learning a procedure with artificial intelligence by first collecting large quantities of images. Subsequently, the system can then be trained using the available data. Although flaw detection can be very fast and robust, all anomalies must be anticipated and taught into the system in advance, since it cannot detect new flaws on the images by itself. Since most of the produced fabric has no faults, collecting this data can be very time consuming. In the case of new materials, it may also be necessary to train a completely new model again.

4. In future there will be an anomaly detection based on AI

An approach not yet used today, solves this problem from the other side: In this case, an AI-based system is trained to recognize a flawless, perfect fabric. It can learn any fine structure and characteristic. If the examined textile deviates from this, the AI thus detects any kind of anomaly. The big advantage: It is not necessary to teach in all possible faults into an AI model. Instead, the AI automatically knows what a “clean” fabric should look like after only a few meters of fabric and can identify anomalous areas. Existing camera systems can be used, only the software has to be reinstalled.

The two pictures below illustrate the technology: The left picture shows a close-up of a piece of fabric with a very faint anomaly in the upper right corner. Our system was able to “extract” this anomaly, which is clearly visible and analyzable on the right picture.

How can I apply this?

sentin GmbH develops and distributes inspection software based on artificial intelligence for industrial use. Take your quality control to the next level – learn more about the sentin EXPLORER in our brochure.