The Industrial Revolution is widely known. But what exactly are NDT 4.0 and NDE 4.0? In this article we first discuss the development of industry and non-destructive testing and evaluation (NDE). Then some new technologies of industry 4.0 are presented, as well as advantages of NDE 4.0.

This article is part of a summary series of Dr. Johannes Vrana‘s & Ripi Singh‘s publication “The NDE 4.0: Key Challenges, Use Cases, and Adaption”. Their research deals with the latest methods of NDT. Their consulting company is a competent partner for research & development in the field of NDT.

Here are the other parts of our series about NDE 4.0:

Contents

What is Industry 4.0?

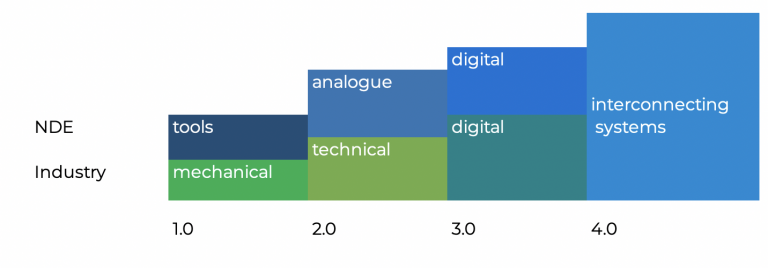

The industrial revolutions are divided as follows:

- 1.0 Mechanical (steam, energy)

- 2.0 Technical (electrical energy, mass production)

- 3.0 Digital (data processing, microelectronics)

In industry, the 4th revolution is currently underway. This is also known as Industry 4.0 and describes the increasing digitalization, such as modern technologies and productions and faster reactions to the sales market.

What is NDT & NDE 4.0?

NDE means ‘non-destructive evaluation’ is the interpretation discipline of non-destructive testing (NDT). Their technological levels can be defined as follows:

- 1.0 Simple Tools (to sharpen the senses)

- 2.0 Analogue Systems (for viewing within the components)

- 3.0 Digital Processing and Automation

The 4th revolution in NDE/NDT is also known as NDE 4.0 and NDT 4.0. It describes the transparency of information, technical support and autonomous and decentralized decisions.

How do industry and NDE compare?

Industry and NDE are each divided into 4 revolutions. In the 1st and 2nd revolution there is hardly any common ground. But already in the 3rd revolution they are very similar. NDE and industry are both in the digital revolution. In the 4th revolution both are in the era of networked systems, which thanks to modern technologies and technical support can make autonomous and decentralized decisions.

NDT 4.0 - The 7 Technologies You Should Know:

Big Data: Describes the ever-increasing amounts of data that are available and are analyzed with the help of systems.

Artificial intelligence (AI): A system that can interpret data and images, learn from them, and use what it has learned to solve tasks with flexible adaptation. So-called neural networks are often used for this purpose.

Digital twins: Based on collected data, simulations can be used to recommend actions or predict decisions, for example. The digital twin is then an entity that has exactly the same preferences. An AI can be used as the basis for such simulations.

Cloud: Data can be stored securely in a cloud and then accessed from any location. It consists of a distributed server network.

Internet of Things: All data, devices and sensors are connected here and can be accessed via a cloud. Often abbreviated as IoT or IIoT for (Industrial) Internet of Things.

5G: Is a mobile data transmission technology and the successor to 4G/LTE and enables the connection of a high number of devices and provides robust real-time data connectivity.

Blockchain: With a blockchain, data can no longer be changed without detection, which improves traceability and trust.

What are the advantages of NDT 4.0 & NDE 4.0?

The possibilities of NDE 4.0 offer some advantages. Due to the availability of a lot of example data (Big Data) there is the possibility to use Machine Learning & Artificial Intelligence (AI). With the help of an AI based system the inspection of the components is improved and therefore the quality is increased.

Also the NDT efficiency can be increased by modern connectivity and advanced computers. Due to the technical support the data exchange and feedback between customers and clients is simplified. In addition, this system is more reliable and tests are easier to trace.

However, since the evaluation process is partly subjective, NDE 4.0 can only be a first step in correctly assessing shots and discrepancies. Likewise, all users of the technology must always be up to date with the latest technology.

How can I use NDT 4.0 & NDE 4.0?

Digital radioscopy (DR) and working with imaging plates is becoming increasingly popular, but other imaging techniques such as phased array (UT) also offer image material that can be digitally evaluated.

In order to save time and nerves during examination and evaluation, the right tool should be used. Often an interpretation of discontinuities is also not unambiguous, so one asks a colleague for advice. The sentin EXPLORER facilitates the evaluation by automatically analyzing and marking of defects.

Take the first step towards NDT 4.0 and NDE 4.0.

Here are the other parts of our series about NDE 4.0: