Marija Bertovic is a chairwoman of the DGZfP subcommittee “Human machine interaction” within the committee “NDE 4.0” and a secretary of the ICNDT specialist international group “NDT reliability”.

In 2017 she was awarded a certificate of merit for her overall contributions to the field of NDT and in 2018 the Scientific Award by the German Society for Non-destructive Testing (DGZfP) for this work

Nowadays Marija Bertovic is advising on how to include human factors into reliability assessments and simulations and how to make sure new technologies (NDT 4.0, industry 4.0, hydrogen) get accepted, are usable and used appropriately.

Marija Bertovic on Research Gate and LinkedIn

Here is a little overview about the questions Marija Bertovic and we talked about:

- Marija Bertovic: Her way to becoming a human Factors Research Scientist in NDT

- Chances for NDT 4.0 and human factors

- Certifications & POD for NDT 4.0

- The international future of NDT

Marija Bertovic about her position in NDT

sentin: Hello, Ms Bertovic. We are pleased that you, as an expert, want to give us and our readers an understanding of the topic. It would be best if you briefly introduce yourself.

Marija Bertovic: – I studied general psychology at the University of Rijeka in Croatia and soon after in 2006 I became a PhD student at the BAM Federal Institute for Materials Research and Testing in Berlin. There I worked in a research group “Reliability of non-destructive diagnosis systems” led by Dr. Christina Müller and conducted research related to various human factors aspects of NDT, e.g. I looked at the usability and understandability of the inspection procedures, at how people work under time pressure, with other people or with automated systems, how people make single and group decisions and have conducted various studies to identify risks involving working with manual and automated (mechanised) NDT systems and to devise measures against those risks. In 2015 I obtained my doctorate degree on this topic. I also worked shortly for the DGZfP and one year as an independent consultant before returning to BAM to a new position in which I lead a work area “Probabilistic safety and reliability analyses/human-factors analyses”.

sentin: In your dissertation you deal with the topic of human factors in NDT. What are the most relevant aspects? How can these be eliminated?

Marija Bertovic: – In my dissertation I focused on the topic of automation in NDT.

“It is widely assumed that human factors can be eliminated with the Increase in automation in NDT. I postulated in my thesis that whereas some human errors can be eliminated, automation will not eradicate the error as it does not completely replace people but instead aids them in their work, thereby changing the task and potentially giving rise to new risks and human errors, that are unknown.“

Human factors will never be eliminated as long as people are involved in the task, whether as designers of the system or its end users. It should also never be our goal to eliminate human factors, as they refer to all the factors that affect people at work in a way that can affect safety, i.e. the individual, the team, the technology, the organisation (including working conditions) and the extra-organisational environment (e.g. the regulations) and their mutual interactions.

“Instead, our goal should be to reduce or eliminate those factors that give rise to human error.”

They include faulty or not understandable procedures, poorly designed human-machine interfaces, difficult working conditions, poor communication, unclear division of responsibilities and many more.

sentin: You are a researcher at the Federal Institute for Materials Research and Testing (BAM). What changes do you see in the coming years for the NDT 4.0 sector in Germany?

Marija Bertovic: I see an increasing need to keep up with the developments in the industry. NDT will need to keep up as It is a vital part of Industrial processes and because new technology developments offer ways of conducting NDT inspections in a more efficient and reliable manner. As a research scientist, I see BAM supporting those attempts by providing support in the development of those systems as well as by making sure those systems get implemented reliably and safely.

Experiences and thoughts

sentin: You do research in the field of Human Machine Interaction (HMI) and are the chair of this working group at the DGZfP. I have a few questions about this:

How well does the communication between people and machines work in NDT?

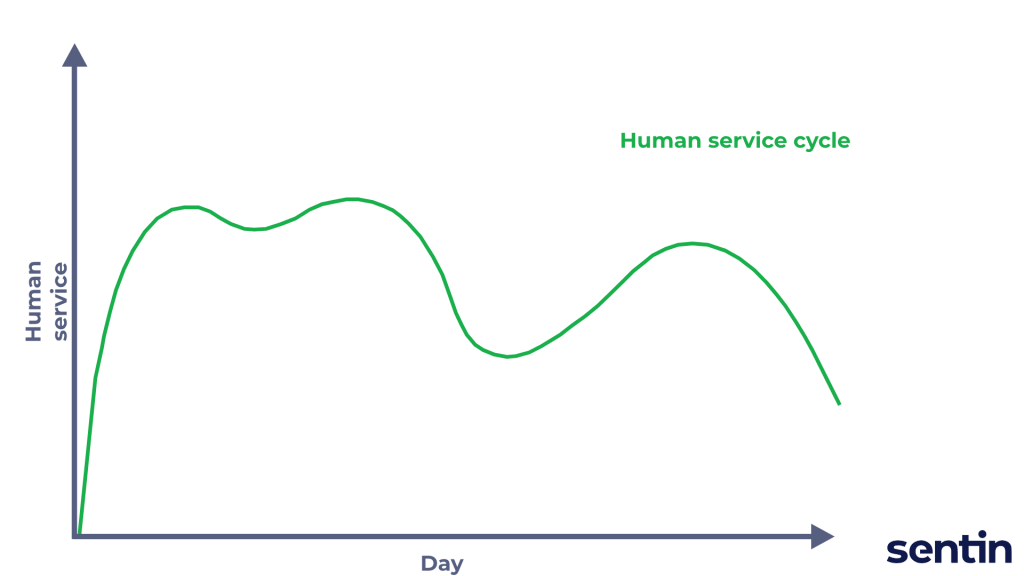

Marija Bertovic: I guess people were always able to communicate with NDT systems. Traditionally a system would be developed in a lab, put on the market, people were trained to use it and people and machines worked more or less good together. Thus, communication between people and machines can be forced and learned by training. However, the more complex technology gets, the more complex training gets and with that the demand on the people rises. In spite of extensive training,

“in situations of high stress, or due to distractions, people are likely to react intuitively and not according to the rules they have learned”

(i.e. a red light will be seen as the alarm, as danger, in spite of training that it is the blue light that signals an alarm). Thus, the more complex technologies get, the more important it becomes to give attention to the design of the technical systems as well as to the interaction between people and the systems to ensure that communication runs smoothly.

In my experience, the development and design of hardware and software in NDT still happens in a lab and gets tested only by a limited amount of people before the systems are used in the field. Rapid development of technologies in the era of Industry 4.0 will show that higher effectiveness, efficiency and satisfaction with the product, as well as a more reliable and effective human-machine interaction can only be achieved if the systems are developed together with the users following human-centred design principles (see ISO 9241-11:2018 and ISO 9241-210:2020).

sentin: How willing is one to work with a machine/computer? To what extent do people trust a hardware or software system?

Marija Bertovic: Trust is a very complex issue and It depends on a variety of factors. For example, trust in a piece of technology (hardware or software) will depend on its capability, reliability, as well as one’s own experience with that system. Moreover, trust can be shaped by individual differences in e.g. attitudes towards technology, one’s own abilities, self-confidence or the extent of risk-taking. According to the Technology Acceptance Model developed by Davis in 1986, the acceptance and, respectively, the use of the system, is affected by the perceived usefulness and the perceived ease of use (both of which can be affected by a variety of external variables, such as usability) that together with the attitude towards using affect the behavioural intention to use and, consequently, its actually use. In other words, the willingness of people to accept and work with a piece of technology is highly affected by its usability, emphasizing again the relevance of user-centred design.

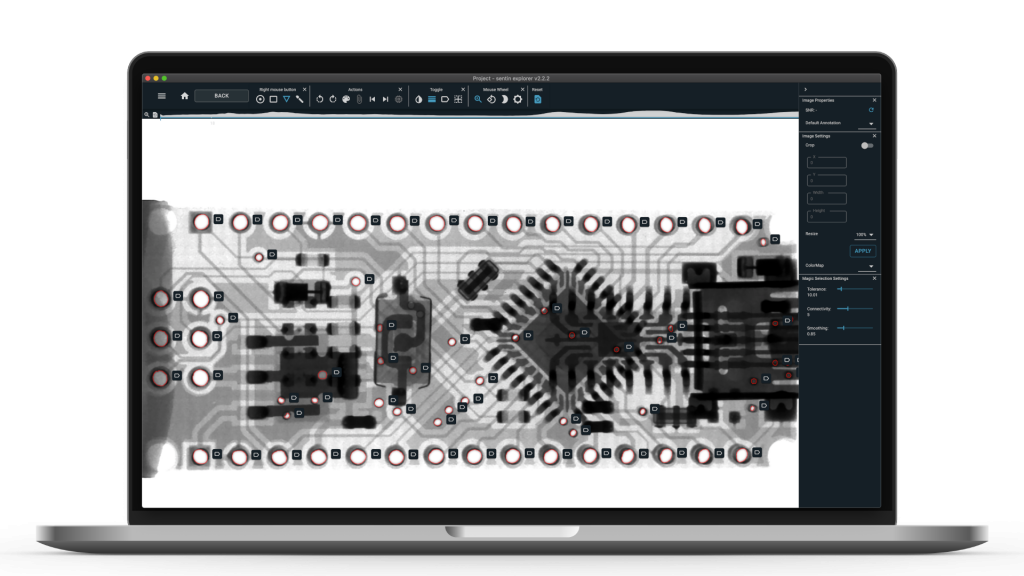

sentin: What examples can you think of spontaneously where a machine or a computer is already helping the inspector? And how exactly can they support the examiner/evaluator?

Marija Bertovic: In my work I came across software solutions that were designed to automatically detect and sometimes even characterise defects. These kinds of software solutions were used as aids to the inspectors, wherein it was the role of the inspector to control and, if necessary, correct the results of the software. I believe this kind of technology will soon become omnipresent thanks to the advances in machine learning.

“With time, the software should be able to do this task independently and the role of people will change from supervising those systems Into solving complex problems that the technology is not yet able to.“

Another example is the use of augmented reality to visualise defects (by visualising signal amplitudes) that can be used in training of the inspectors. This kind of technology will for sure find wider application in the field by visualising not only present defects but also results from past inspections, examples from books, procedures, allowing communication with people off site, thereby aiding the inspector in making his judgment on the presence of a potentially critical defect.

About Marija Bertovic

Senior human factors research scientist at Federal Institute for Materials Research and Testing

DGZfP

- Member of the German Society for Non-Destructive Testing

- Science Award 2018

BAM

- Coordinator of the NDT department WG “NDT-AI”

Marija Bertovic is an Awarded and experienced research scientist in the area of human factors in reliability of non-destructive testing (NDT). Actively pursuing projects related to human machine interaction (HMI) in industry 4.0 (artificial intelligence, NDT 4.0, machine learning, user experience, software development, augmented reality etc.).

Chairwoman of the subcommittee “Human Machine Interaction” of the DGZfP technical committee on NDT 4.0; Secretary of ICNDT Specialist international group “NDT reliability” and coordinator of the NDT department WG “NDT-AI” (BAM)

Skilled and experienced in usability testing, risk assessments, experimental method and coordination, human factors training and consulting.

She is a receiver of the Science Award 2018 by the German Society for Non-Destructive Testing (DGZfP) and repeatedly a keynote and plenary speaker.

Member of the German Society for Non-Destructive Testing (DGZfP), Academia NDT International and Human Factors and Ergonomic Society – European Chapter.

See how AI in NDT works

What is the sentin EXPLORER?

As Marija Bertovic said, more and more people become trained to use AI in Non-Destructive Testing. “In situations of high stress, or due to distractions, people are likely to react intuitively and not according to the rules they have learned“ For these cases, there are softwares which support the human inspectors. She talks about higher effectiveness, efficiency and satisfaction, if the rapid development of technologies in the era of Industry 4.0 goes on. Trust in a piece of technology will depend on its capability, reliability, as well as one’s own experience with that system. This is a reason for the fact, that the willingness of people to accept and work with a piece of technology is highly affected by its usability, emphasizing again the relevance of user-centred design. Marija Bertovics thoughts about the future are that with time, the software should be able to do their tasks independently.

The sentin EXPLORER is a tool to automate such inspection or image evaluation tasks. Our customers sometimes produce thousands of images per week, all of which have to be reliably checked. Therefore we give you the power to perform evaluations with the help of artificial intelligence and to find defects more reliably or gain new insights.

If you want to learn more: The 5 Types – What is Non-Destructive Testing (NDT)?