In the age of Industry 4.0, many companies perceive digitization to be associated with a growing degree of data-driven activity. I share this view. To be more precise, I see 3 important digitization steps in which companies have to integrate themselves before they plan and carry out corporate strategic activities. But first I would like to explain a few terms from the English language regarding digitization, based on the Forbes article [1] Digitization,Digitalization, And Digital Transformation: Confuse Them At Your Peril (2018).

The English language differentiates more precisely than the German language between digitization, digitalization and digital transformation. These three terms in turn denote the state of companies in relation to digitisation.

“Digitization is the process of changing from analog to digital form” (Gartner’s IT Glossary)

In relation to the business environment, this term describes, for example, the digitization of documents and information, the first stage of digitization according to German terminology.

“Digitalization[…] is the process of employing digital technologies and information to transform business operations” (Digitalization and the American Workforce)

The next step after the pure digitalization of documents is that of processes. Nowadays, processes are often carried out partially analogously. Often process information is already digitized in the form of documents (e.g. Excel tables), but is evaluated or edited in the process in analog form. The digitalization of processes is often accompanied by a degree of automation. With the advent of BDE, MDE or MES systems, for example, production processes have been digitized and can sometimes even be viewed digitally in their entirety. The aim of process digitisation is to achieve higher efficiency and increased transparency of the process.

The digital transformation of companies and business units, on the other hand, has a further focus. It is often a matter of setting up and offering new business models based on digital technology or the findings of digitization and digitization on a project basis. This is referred to as innovation projects, which, unlike the activities mentioned above, require less understanding of technology than customer focus.

In everyday business practice, the three terms are often mixed up, which makes it difficult to formulate a clear corporate positioning and a resulting strategic route. The aforementioned “new business models” are often the desire of many industrial companies to increase turnover and to develop competitive advantages in what is often a highly competitive (classic) market. In very few cases the resulting requirements are not known to the companies themselves. For example, innovation projects in new business are accompanied by cultural, strategic and resource-related risks. The strong uncertainty of new business development inevitably causes these risks. Expertise is also required in the area of new business development, which is often lacking in traditional companies. Industrial companies, for example, run the risk of equating digitization with new business development and, to a certain extent, of “burning themselves out” with such comprehensive projects.

Practice shows that developing new business in the digital sector is a good idea to build up digitization initiatives. Thus, an initial digitization of existing processes is recommended. Building on this, internal potential for improving efficiency can then be tapped. In the area of production, this could include, for example, the use of data to identify quality-relevant process parameters and their influence in interaction with each other on the final quality result of the manufactured component. This is accompanied by a growing data treasure through the acquisition and combination of relevant process parameters from different sources (e.g. production-related systems (MES, BDE, MDE), sensor technology or external parameters such as the hall temperature. On the basis of this dataset, new innovation initiatives can be developed, which can generate interesting long-term business models through early customer integration. Important here: If I approach external parties with ideas for digital business models, I should myself demonstrate a certain degree of digitalization of my business processes. How else can a provider company credibly position itself?

[1] Digitization, Digitalization, And Digital Transformation: Confuse Them At Your Peril (2018)

How can an examination be performed digitally?

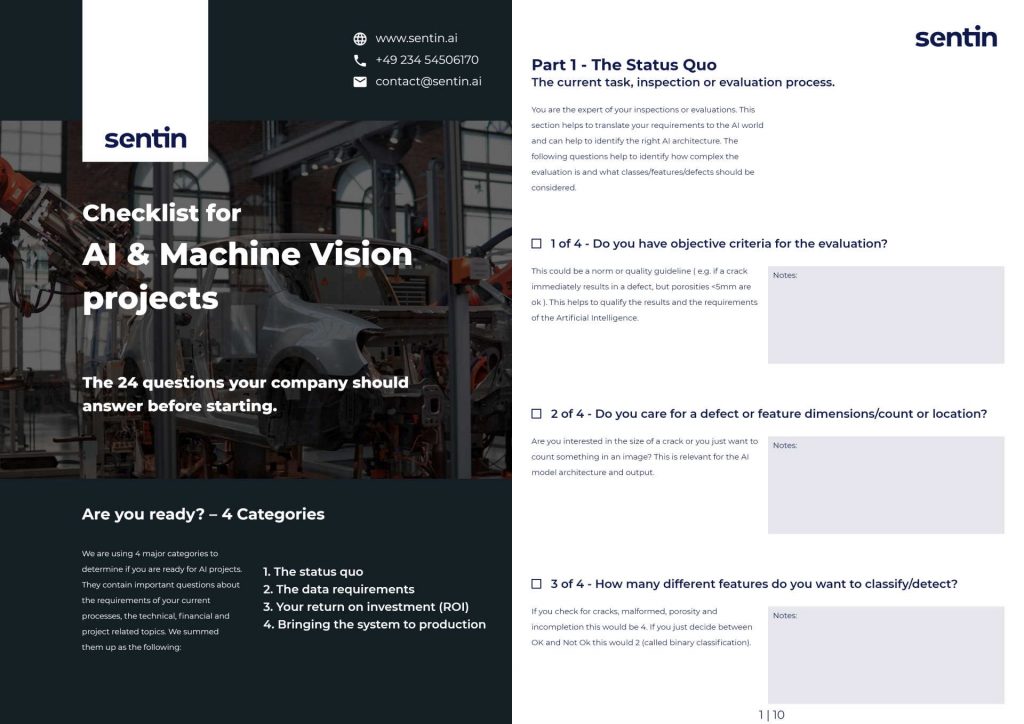

sentin GmbH develops and distributes inspection software based on artificial intelligence for industrial use. Take your quality control to the next level – learn more about the sentin EXPLORER in our brochure.