Yesterday Christian presented our project for automatic weld seam inspection at the Industry Tech Innovation Night at digihub. The audience voted and our usecase was well received. Christian was then able to go into even more detail.

First round

In the first session, Christian explained the potential of artificial intelligence methods in non-destructive material testing (NDT). Especially in the quality inspection of consumer goods, the 100% inspection of automotive parts or component testing for plant safety, processes can be optimized with machine learning. This enables companies to increase the quality of testing and reduce the time required. The danger of a lack of qualified personnel in certified inspectors can also be put into perspective in this way.

He outlines how the sentin.ai vision product could revolutionize the inspection process and introduces the sentin team.

The vote

Afterwards or during the other seven pitches an online voting took place. The use case and the presentation were convincing, so that we could move on to the second round. In addition to two other presentations, the use case of automated RT inspection of weld seams was then specifically addressed.

Second round

After a short transition of the moderation and great pleasure on our part, Christian presented the problems that exist in the NDT of pipes. In addition to the lack of skilled personnel, the safety requirements for the process industry and the detection of damage and leaks are particularly relevant. Today’s radiographic image acquisition and the manual interpretation of these images require high concentration and are associated with enormous costs. The AI models we develop help the inspector to perform this task faster and with less uncertainty.

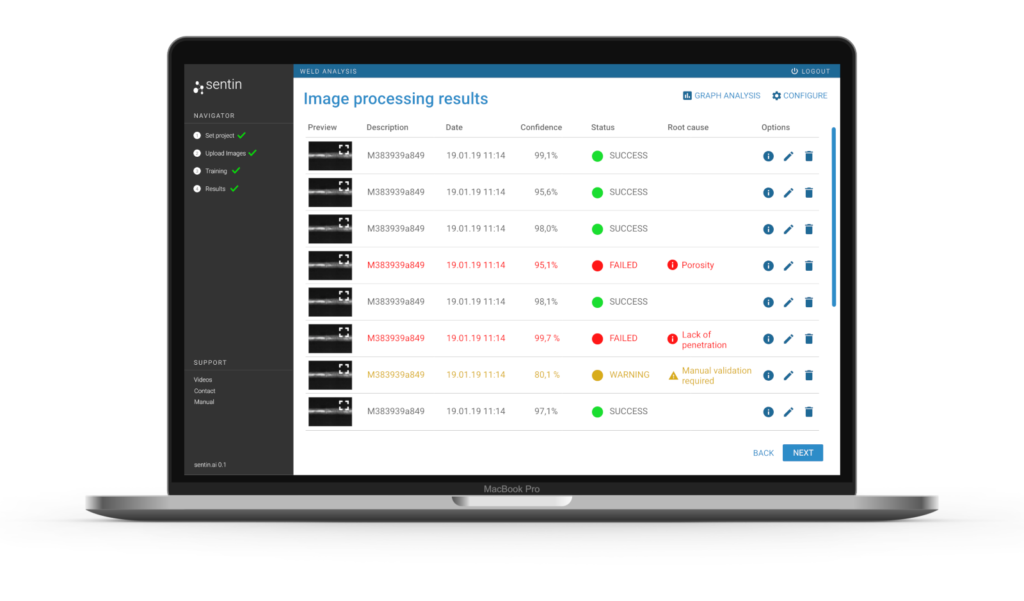

A user-friendly user interface and a flexible programming interface should revolutionize this process and take NDT to a new level. Christian also describes that we are currently pursuing and seeking projects in the field of NDT and quality assurance. Our extraordinary expertise and mechanical engineering background allows us to work fast and domain-oriented.

Conclusion

All in all a successful event with many interesting presentations. We were able to make some contacts and are pleased that the digihub invited us to such an innovative event. We are curious what the industry and NDT can expect in the near future.

In order to save time and nerves during testing and evaluation, you should use the right tool. The sentin EXPLORER facilitates the evaluation by automatically analyzing and marking of discrepancies.

External and internal characteristics play a role in the evaluation of welds. Non-destructive material testing such as visual inspection (visual inspection – VT) or imaging methods (e.g. radiographic testing with X-rays or gamma rays – RT, or ultrasound with phased array – UT) can be used to examine them for cracks or pores, for example.

More about this in our article: